Products

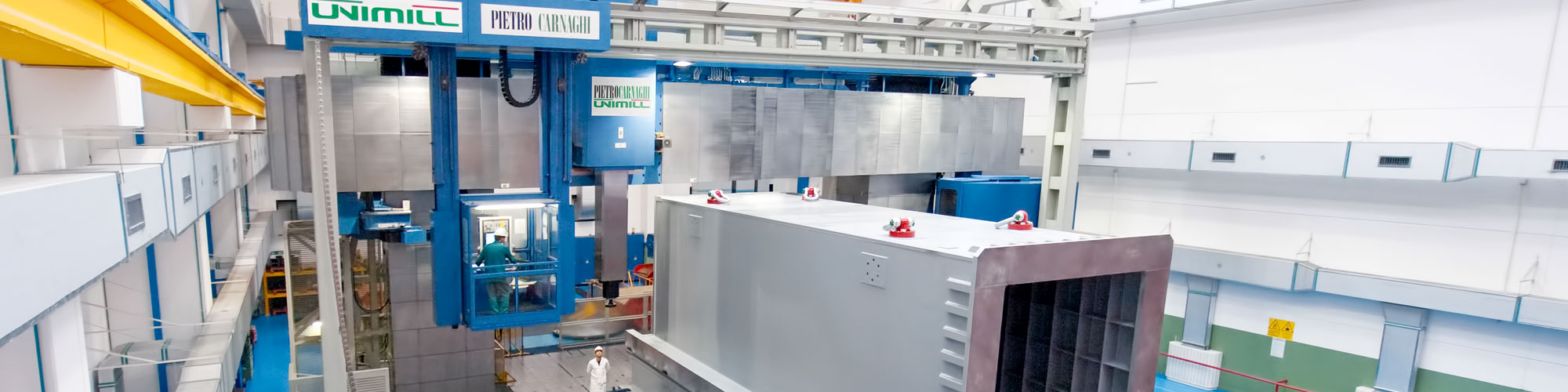

Pallet Systems

Different types of pallet system are available for Pietro Carnaghi machines:

ROTATING PALLET (ATF TYPE): the most compact solution. Two pallets rotate at 0° - 180° on a revolving base. Available for pallets up to mm 2000(78.7 in).

TRANSLATING PALLET:

The basic version provides a 2 pallet changing system, having the capability to increase the number of pallets.

The system is complete with the following units:

- Rotational Shuttle Unit (RSU): it distributes the pallet to the station required

- Rotational Positioning Station (RPS) to load/unload and center parts. This station has the same underbase unit as in the main spindle of the vertical lathe.

- Parking stations for pallets (SPS)

BASE WITH 2 MOVABLE TABLES (translating Y axis):

System with linear axis on hydrostatic guideways. This solution meets the highest speed in exchanging pallets with the capability to use the Y axis from milling/drilling operations out of the centerline axis.

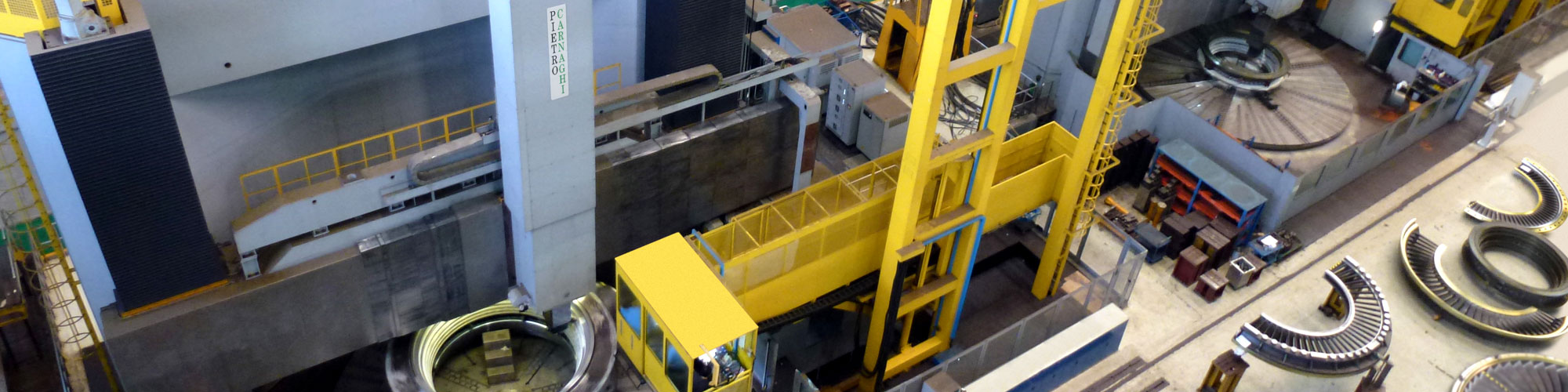

FMS CELL SYSTEM:

System of distribution of the pallets with a rotational shuttle unit that runs on rails and serves 2 or more machines. To complete the system, here the following units:

- Rotational Positioning Station (RPS) to load/unload and center parts. This station has the same underbase unit as in the main spindle of the vertical lathe.

- Parking stations for pallets (SPS)

![]()

PIETRO CARNAGHI WEBSITE DISCLAIMER

COPYRIGHT

PIETRO CARNAGHI (PC) PROPRIETARY INFORMATION

The information contained In this website and in related documents (texts, images, tables etc.) may contain information owned by PC.

This information may not be used, passed on to others or reproduced without the written consent of PC. Unauthorised use is prohibited.

PRIVACY POLICY

Information pursuant to Art. 13 Leg. Dec. no. 196 of 30 June 2003 (Personal data protection law), and Art. 14 of Regulation no. 679/2016 GDPR.

The personal data provided by the User shall be placed in a special computerised database so that it can be used to access the requested services. The data controller is Pietro Carnaghi S.p.A., with registered office in Villa Cortese (MI), Via S. D'Acquisto 7.

Pietro Carnaghi S.p.A., as data controller, informs you that the email address requested at the time of registration and the other personal data provided, will be processed with the consent of the person concerned, in order to provide the information requested by the User.

Pursuant to Art. 7 of Leg. Dec. no. 196 of 30 June 2003, (Personal data protection law) and Art. 17 of Regulation no. 679/2016 GDPR, the User has the right to obtain confirmation of the existence or otherwise of personal data concerning him/her, even if not yet recorded, and the communication of such information in an intelligible form.

Furthermore, the User has the right to obtain information on the following:

• source of personal data;

• purposes and method of processing;

• logic applied in the event of processing carried out with the aid of electronic means;

• identification details of the Data Controller, data supervisors and the representative designated pursuant to Art. 5, paragraph 2 of Leg. Dec. no. 196 of 30/06/2003;

• parties or categories of parties to whom personal data may be communicated or who may have access to such personal data in their capacity as designated representative in the Country’s territory, or as managers or persons in charge.

Furthermore, the User has the right to obtain:

• the updating, correction or, if of interest, additions to personal data;

• the cancellation, transformation into anonymous form, or blocking of data processed in violation of law, including those which need not be retained for the purposes for which the data were collected or subsequently processed.

• certification that the parties to whom the data have been transferred or disseminated have been made aware of the operations specified in the above points, also as regards their content, except for the case where notification proves impossible or requires the use of means clearly disproportionate to the right being protected. Finally, the User has the right to object, in whole or in part:

• on legitimate grounds, to the processing of personal data concerning him/her, even if relevant to the purpose of the collection;

CV MANAGEMENT LINK DISCLAIMER

We inform you that the information collected about the interested party shall be managed and stored in compliance with EU Regulation no. 679/2016 GDPR and the Privacy Leg. Dec. 196/03 and subsequent amendments. The data controller is Piero Carnaghi S.p.A with registered office in Villa Cortese (MI), Via S. D'Acquisto 7 and the person in charge of data processing is the Head of the Human Resources Office. Finally, it should be noted that the person concerned in regards to his/her personal data also has, where applicable, the rights referred to in Articles 15-21 GDPR (Right of access, Right of rectification, right to be forgotten, right to restriction of processing, right to data portability, right of objection), by sending an email to [email protected] as well as the right to submit claims to the Guarantor Authority.